Products Category

Contact Us

Tel: +86-18 423 717 818

E-mail: sales@cqoptics.com

Add: No. 5, Torch Ave, Jiulongpo District, Chongqing,400080 China 3rd Zone, Gongdatang, Jiangdong Street, Yiwu City, Zhejiang Province 322099 CHN

Skype: 27393442@qq.com

WeChat: Matrip023

whatsapp: +86 18423717818

Industry News

>> Float Zone Crystal Growth

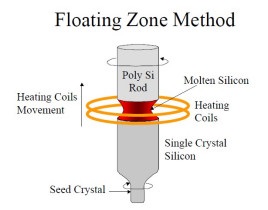

Floating zone method was proposed in the 1950s and soon applied to crystal preparation technology. In the suspension zone melting method, the cylindrical silicon rod is fixed in the vertical direction and heated in argon atmosphere with a high-frequency induction coil to form droplets between the bottom of the rod and the coaxially fixed single crystal seed crystal close to its lower part, and the two rods rotate in the opposite direction. Then, the melting zone formed only by surface tension between polycrystalline rod and seed crystal is gradually moved upward along the rod length to convert it into single crystal.

The oxygen content and impurity content of monocrystalline silicon prepared by Floating zone method are very low. After many times of zone melting and refining, monocrystalline silicon with low oxygen and high resistance can be obtained. If the monocrystalline silicon is put into a nuclear reactor and doped by neutron transmutation doping method, the impurities will be distributed very evenly. The resistivity of monocrystalline silicon prepared by this method is very high, which is especially suitable for making power electronic devices. Monocrystalline silicon prepared by Floating zone only occupies a small market share.

Floating zone method is carried out in a sealed reaction chamber filled with argon. First, a polycrystalline silicon rod with a length of about 50 to 100 cm is vertically placed in the high-temperature reaction chamber, the heating coil melts the end of the silicon rod, and then melts the seed crystal into the melted area. The melt will be suspended between the seed crystal and the polycrystalline rod by the surface tension of the molten silicon, Then, the heating coil slowly rises upward to melt the polysilicon rod above the molten silicon. At this time, the molten silicon near the end of the seed crystal begins to solidify, forming the same crystal direction as the seed crystal. When the heating coil sweeps the whole silicon rod, it can be transformed into a crystal rod of monocrystalline silicon.

When using this method to grow silicon single crystal, the melting zone is suspended between the polysilicon rod and the single crystal grown below, so it is called suspended zone melting method. Because quartz crucible and other containers are not used in the process of melting and growing silicon single crystal, it is also called crucible free zone melting method. Because the density of silicon melt is small (2.3 g / cm) and has a certain surface tension, coupled with the floating effect of high-frequency electromagnetic field, the melting zone is easy to remain stable.

In addition to the above monocrystalline silicon preparation, the Floating zone method can also be used to purify polycrystalline silicon. The latter mainly uses the segregation effect and evaporation effect of impurities in silicon to obtain high-purity polycrystalline silicon. Zone melting can be carried out in protective atmosphere (argon and hydrogen) or in vacuum, and can be purified repeatedly (especially faster evaporation in vacuum). It is especially suitable for preparing high resistance silicon single crystal and detector grade high-purity silicon single crystal. In addition, Floating zone method is one of the means to test the purity of polycrystalline silicon.

The temperature of the area should be slightly higher than the melting point of the material. During the movement of the material rod from top to bottom, the heated part experienced the process of melting and crystallization, and finally formed a single crystal rod. In the whole process, the material rod is overhead and does not contact with any container, which avoids the pollution of crucible to the material, and can be used to prepare high-purity crystals. This method is especially suitable for preparing single crystals of high melting point metals or oxides. When used for purification, the above process is often repeated several times. Due to the different solubility of impurities in the solid at different temperatures, the impurities in the solid can be collected at one end of the rod.

Floating zone has two main disadvantages. One is that the interface between melt and crystal is complex, so it is difficult to obtain stacking fault free crystals. The other is that its cost is very high, because it requires high-purity polysilicon rods as raw materials.

Evaporation Materials

Evaporation Materials